|

Jiangsu Aidy Machinery Co.,Ltd.

|

baby diaper machinery

| Place of Origin: | Jiangsu, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

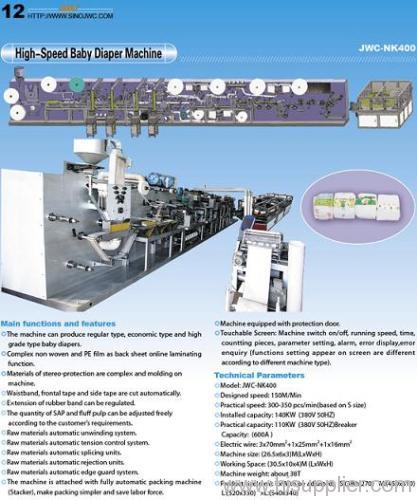

4 sizes baby diapers production line, quality mainly depends on raw materials quality

Functions And Features

It can produce both economic and high-grade products.

Raw materials Automatic unwinding system.

Raw materials Automatic tension control system

Raw materials Automatic feeding system

Raw materials Automatic web guiding system

Raw materials Automatic inspecting for raw material defect

Raw materials Automatic inspecting for raw material splicing

Raw materials Automatic rejection system

Fixed amount feeding system for fluff pulp and SAP

Stacker connects with the main machine, to realize automatic arranging and bag-feeding function.

Man-machine interface

Hot melt applicator outer-fixed(bridge style)

Main Technical Parameters

Type: NK300

Designed speed:130m/min

Practical speed: 250-300pcs/min

Installation capacity:120KW (Including hot melt applicators)(380V 50Hz )

Practical capacity: 95 KW (Including hot melt applicators) (380V 50Hz ) Breaker Capacity : 400A

Electric wire: 3x70mm2+1x25mm2+1x16mm2

Machine size:(26x26x3)m (LxWxH)

Working size: (30x17x4)m (LxWxH)

Air compressor: 1.3m3/min >0.6Mpa

Total weight:38T

Product specification(mm):(LxW)(it can as your order)

S: 380x270 M: 450x310 L: 520x330 ×L: 540x340

Container: 2x40HQ+1x20GP

Options Devices

Defect scan system for raw material

Position checking system for frontal tape, side tape and ADL

Frontal Tape location detection and cutting system

Safety guard system(according to CE standard)

Fluff pulp Feeding system adopts aggregate device or forming drum to be chosen by customer.

Ultraviolet rays sterilizing system

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Baby Diaper

Disposable Baby Diaper

Big Baby Diaper

Baby Diaper Machine

Baby Adult Diaper

Super Diaper Baby

More>>

.jpg)

.jpg)

.jpg)

.jpg)